Electrical traction contacts:

They are essential components in modern railway systems. They enable the transmission of power, control signals, and data between the different units or carriages of a passenger train. Their reliability and technical design are key to ensuring operational continuity, safety, and efficiency in rail transport.

What are traction contacts?

These are electrical, electromechanical, or hybrid connectors that form part of the coupling system between carriages on a train. These contacts allow electrical power, control signals (such as braking or door opening), and digital communication to be transmitted between the different vehicles, enabling them to operate as a single unit.

Types of traction contacts

1. Manual: used on older trains or locomotives pulling carriages, they require manual connection of electrical cables.

2. Automatic: integrated into couplings such as Scharfenberg or Dellner, they connect automatically when the carriages are coupled.

3. Electromechanical: they combine electrical contact with motorised or mechanical operation, common in high-speed trains.

Importance of traction contacts in train operation

On a passenger train, every electrical, mechanical, or pneumatic component plays a critical role in ensuring its operation and safety. Traction electrical contacts, despite being discrete and relatively small components, are essential for the proper functioning of all the systems integrated into a train. Their main responsibility is to ensure electrical continuity and control between coupled vehicles, allowing the train to operate as a synchronised unit.

From traction to brakes, communication systems, air conditioning, and signalling, all depend on the correct transmission of signals and energy through these contacts. A failure in these elements can result in anything from operational disruptions to serious safety issues. For this reason, they are considered critical components and must meet rigorous standards of reliability, resistance to vibrations, adverse environmental conditions, and wear and tear from frequent use. Preventive maintenance, periodic inspection, and manufacturing quality are fundamental aspects of the technical management of any railway operator.

Manufacturers and real-life examples

• Scharfenberg traction contacts: used on commuter trains and trams. Commonly used on AVE high-speed trains and regional trains.

• Dellner traction contacts: integrated into Stadler and CAF trains.

• Siemens traction contacts: present in Velaro and high-speed trains.

• Alstom traction contacts: used in trams and multiple units such as Coradia or Citadis.

• CAF traction contacts: designed for commuter fleets, such as Civia trains.

• Stadler traction contacts: FLIRT and KISS systems, with automatic multipole connectors.

• Renfe traction contacts: both on AVE and commuter trains, integrated connections are used for signals, power and brakes.

Applicable regulations

Traction contacts must comply with international standards such as:

– UIC 558, 552, 541-5

– IEC 61375 (train communication)

– EN 45545 (fire safety)

– EN 50208 and EN 50567 (railway couplings and connectors)

Typical applications

These contacts enable:

– Control of the train from a single cab.

– Transmission of electrical power between carriages.

– Synchronised brake operation.

– Safety and passenger communication.

Other notable manufacturers: Voith

In addition to the manufacturers already mentioned, Voith is internationally recognised for its railway coupling solutions, including automatic coupling systems with integrated electrical contacts. Voith traction contacts are used in various types of passenger and freight trains, and are designed to operate accurately under demanding conditions. Their solutions include power, signal, and data transmission modules that are integrated into Scharfenberg-type automatic coupling heads.

Voith stands out for offering robust components with high vibration tolerance and compatibility with UIC and IEC standards, making them suitable for international operations. Its traction contacts are designed to facilitate maintenance and reduce coupling time between units, increasing the operational efficiency of modern fleets. They are used by train manufacturers such as Stadler and, in certain models, are adapted for suburban and interurban services.

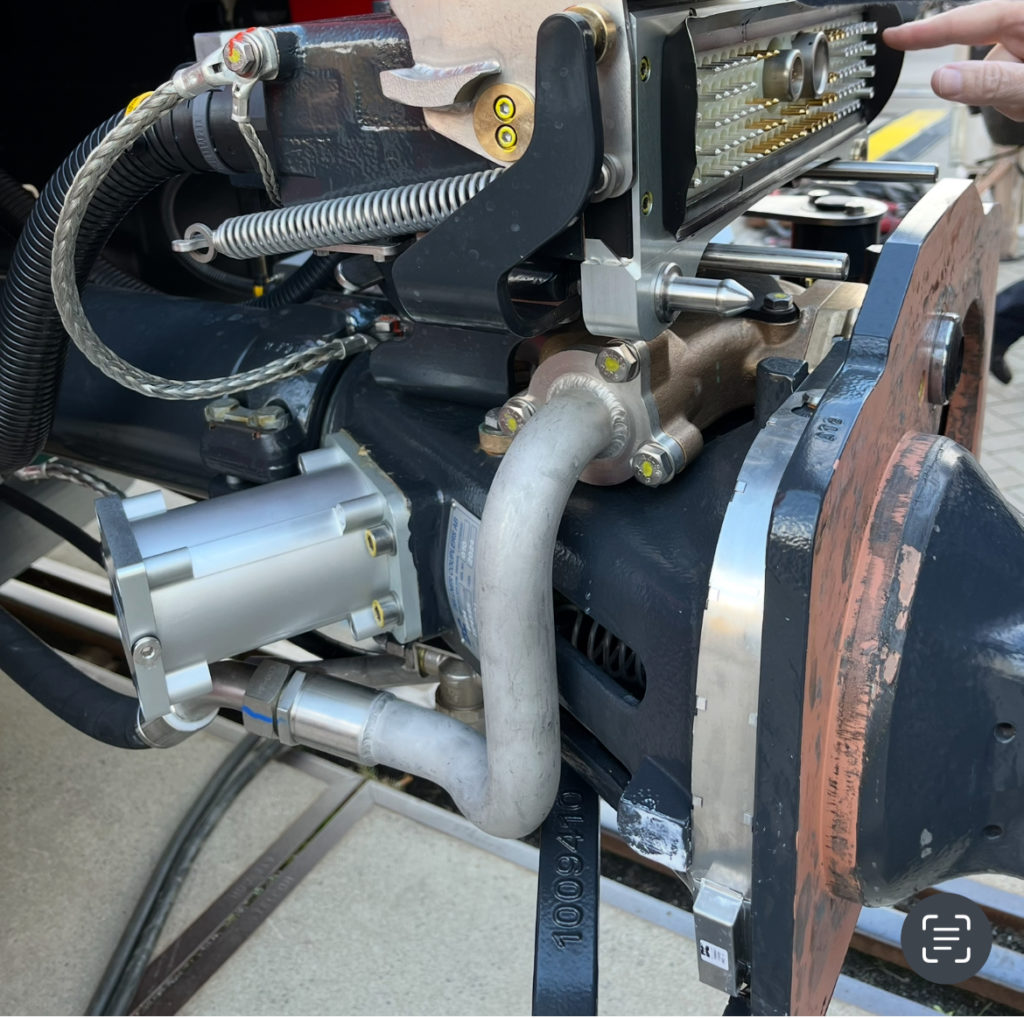

Graphical examples of traction contacts

The following illustrations show a typical example of electrical traction contacts in modern trains, where multiple functions are integrated into a compact and robust system.